Quality Control

Product quality is closely related to customer's benefit and our also market development. We have been always rigorous in quality control, and we have introduced a multitude of state of the art test equipment and professional QC staff. Our quality control on workstation crane, port crane, casting crane, electromagnetic overhead crane, explosion proof crane, waste handling crane, electric hoist, and other material handling machinery includes raw material test, plates cutting test, weld flaw detection, girder test, trolley wheel test, etc.

Lab

- Lab

- Impact Testing Machine

- Temperature Controller

- Durometer

- Water Distiller

- Sample Cutting Machine

- Sample Pre-grinding Machine

- Mn, P and Si High Intelligent Analyzer

Test Flow

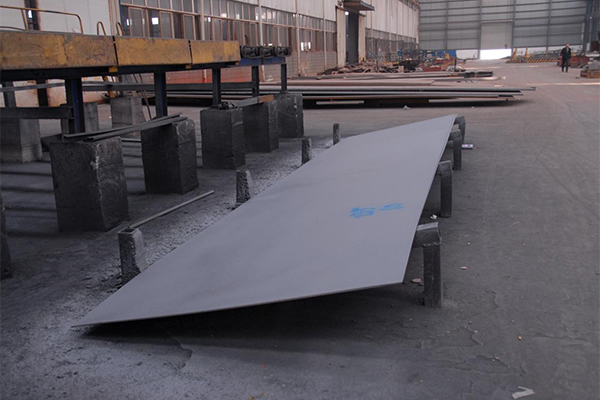

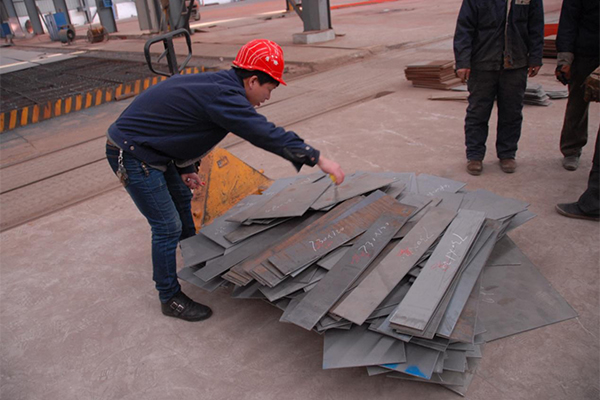

- Steel Plate Pretreatment

- Material Feeding Test to Plate Shearing Machine

- Material Feeding Test to CNC Cutter

- Butt Weld Ultrasonic Flaw Detection

- Test to Height Differences of Crane Wheels' Origin of Force

-

Test to Girder and Trolley Track

- Trolley Track Gauge Measurement

- Girder Side Curve Test

- Vertical Deviation Test to Girder Web

- Wave Degree Test to Girder Web

- Span Test

- Diagonal Test to Crane Span Structure

- Lateral Deviation Detection to Crane Wheels

- Vertical Deviation Detection to Crane Wheels

- Upper Cover Plate Lateral Deviation Detection

- Trolley Wheels Flatness Detection

- Trolley Wheel Track Gauge Measurement

- Trolley Wheels Diagonal Test

- Trolley Wheel Lateral Deviation Detection